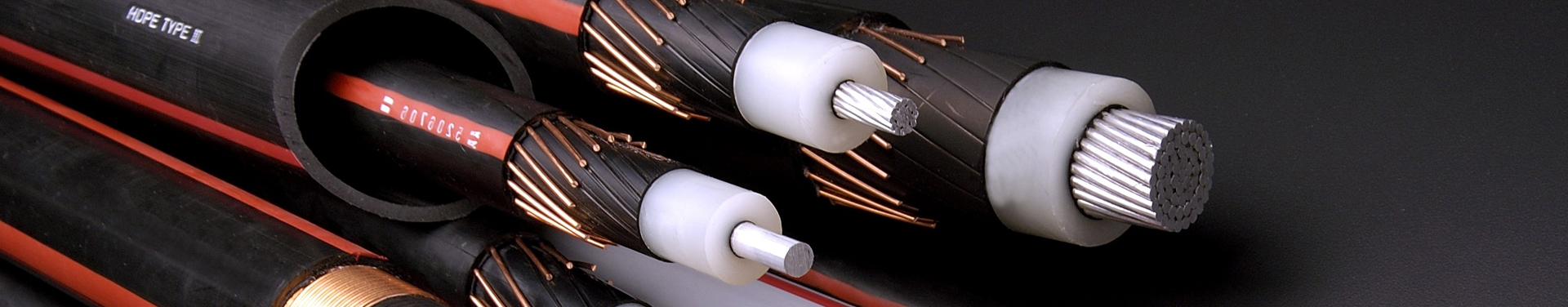

professional production of various kinds of cables and associated electronic accessories products factory

1、 Control of cables:

In metal pressure processing, the technical processing method of metal drawing is to force the metal through the mold under the action of external forces, compress the cross-sectional area of the metal, and obtain the required cross-sectional area shape and size.

According to the drawing process, it can be divided into single wire drawing and patterned drawing.

2、 Pattern:

In order to improve the flexibility and overall integrity of wires and cables, weaving two or more single wires together in the specified direction is called weaving.

The pattern making process is divided into: conductor pattern making, cable forming, weaving, steel wire wrapping, and winding.

3、 Wrapping:

According to the different performance requirements for wires and cables, specialized equipment is used to wrap different materials on the outside of the conductor.

The coating process is divided into:

1. Squeezing: materials such as rubber, plastic, lead, aluminum, etc.

2. Vertical package: rubber, wrinkled aluminum strip material.

3. Wrapping: Ribbon paper tape, mica tape, alkali free glass fiber tape, non-woven fabric, plastic tape, etc., and linear fiber materials such as cotton yarn and silk.

4. Dip coating: insulation paint, asphalt, etc